📌 MAROKO133 Update ai: Scientists create living robots with customizable movement

A brand-new engineering approach at Carnegie Mellon University is creating “designer” biological robots using human lung cells.

Known as AggreBots, these microscale living machines may one day traverse the body to deliver therapeutic or mechanical interventions once their motility patterns are fully controlled.

Biobots are microscopic, man-made biological machines capable of autonomous movement and programmed behaviors.

Traditionally, researchers have relied on muscle fibers to power these tiny robots, enabling them to contract and relax like real muscles.

A promising alternative lies in cilia, the nanoscopic, hair-like propellers that move fluids in the body or help some aquatic creatures, like Paramecium or comb jellies, swim.

Controlling the exact shape and structure of cilia-powered biobots, or CiliaBots, has remained a significant challenge.

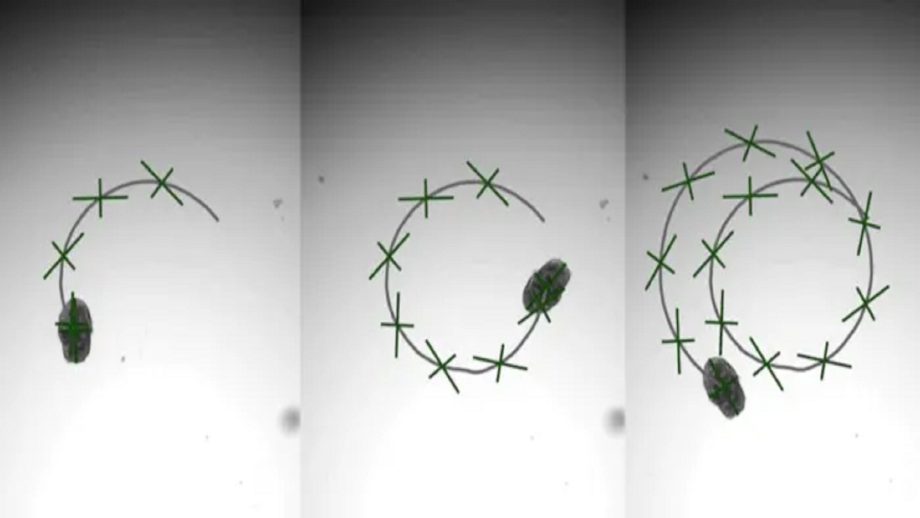

The Ren lab at Carnegie Mellon has developed a novel modular assembly strategy for CiliaBots. By spatially aggregating tissue spheroids engineered from lung stem cells, they can create AggreBots with customizable motility.

The approach allows the inclusion of spheroids bearing genetic mutations that render specific cilia regions immotile.

Controlled cilia for precision

Dhruv Bhattaram, first author and biomedical engineering Ph.D. student, compared the method to removing oars from selected locations on a rowboat while paddling. “We’re pushing forward an alternative method of powering biobot tissues with our AggreBots,” he explained.

“Through the process of fusing together different spheroids into different shapes, together with the inclusion of nonfunctional spheroids, we can precisely control the location and abundance of cilia propellers on the tissue’s surface to direct CiliaBot behavior for the first time. This is a seminal step forward that we and others can invest time into for productive outcomes.”

Victoria Webster-Wood, associate professor of mechanical engineering, added, “The AggreBots approach adds a new design dimension to these types of biobots and biohybrid robots. Being able to combine different ciliated and non-ciliated elements modularly will allow future researchers to create biobots with specific engineered mobility patterns. Because the AggreBots are made entirely from biological materials, they are naturally biodegradable and biocompatible, which may enable their direct application in medical settings in the future.”

Medical and research promise

The platform could benefit a broad range of users, including the biorobotics community, clinicians, and medical researchers studying cilia-related diseases such as primary ciliary dyskinesia or the thick mucus in cystic fibrosis.

Notably, CiliaBots can be made from a patient’s own cells, offering the potential for personalized therapeutic delivery vehicles without immune rejection.

Xi (Charlie) Ren, associate professor of biomedical engineering, emphasized, “Motility matters, because the body is a complex environment. Cellular delivery of therapeutics has great potential, but without a proper propulsion mechanism, cells can easily get stuck.

We’ve laid down a path that people can use to control CiliaBot motility. From helping us understand the health impact of environmental hazards to facilitating in vivo therapeutic delivery, CiliaBots have a swath of potential uses, and it’s exciting to be part of their evolution.”

AggreBots represent a major step in biohybrid robotics, combining modular design, biodegradable materials, and precise control over motility to open up possibilities for research, personalized medicine, and future therapeutic applications.

The study has been published in the journal Science Advances.

🔗 Sumber: interestingengineering.com

📌 MAROKO133 Hot ai: Solid-state sodium batteries that retain performance down to s

Researchers have developed all-solid-state sodium batteries that retain performance down to subzero temperatures. Developed by researchers from the University of California, San Diego, the batteries could help replace lithium-based energy devices.

Researchers also revealed that sodium is an inexpensive, plentiful, less-destructive alternative, but the all-solid-state batteries they create currently don’t work as well at room temperature.

They heated a metastable form of sodium hydridoborate up to the point it starts to crystalize, then rapidly cooled it to kinetically stabilize the crystal structure. It’s a well-established technique, but one that has not previously been applied to solid electrolytes.

Sodium chemistries

That familiarity could, down the road, help turn this lab innovation into a real-world product, according to researchers.

“It’s not a matter of sodium versus lithium,” said Y. Shirley Meng, Liew Family Professor in Molecular Engineering at the University of Chicago Pritzker School of Molecular Engineering (UChicago PME), who is also affiliated with the University of California San Diego Qualcomm Institute.”

“We need both. When we think about tomorrow’s energy storage solutions, we should imagine the same gigafactory can produce products based on both lithium and sodium chemistries. This new research gets us closer to that ultimate goal while advancing basic science along the way.”

The research team also highlighted that sodium chemistries are attractive, yet sodium solid electrolytes show limited room-temperature ionic conductivity.

Computational and experimental data

UC San Diego team’s work combines computational and experimental data to evaluate the metastability of a sodium hydridoborate and show that rapid cooling from the crystallization regime kinetically locks the orthorhombic phase with fast Na+ mobility.

Researchers stressed that when paired with a chloride-based solid-electrolyte-coated cathode, this metastable phase enables thick, high-areal-loading composite cathodes that retain performance down to subzero temperatures.

“Because the underlying principle is kinetic stabilization of a diffusion-favorable anion framework, this approach is transferable to related hydridoborates and other anion-cluster chemistries. This work provides a practical design strategy and processing guidelines for high-performing solid electrolytes,” said researchers in a study published on Joule.

Co-first author Sam Oh of the A*STAR Institute of Materials Research and Engineering in Singapore stated that the research helps put sodium on a more equal playing field with lithium for electrochemical performance.

“The breakthrough that we have is that we are actually stabilizing a metastable structure that has not been reported,” Oh said.

“This metastable structure of sodium hydridoborate has a very high ionic conductivity, at least one order of magnitude higher than the one reported in the literature, and three to four orders of magnitude higher than the precursor itself.”

Pairing that metastable phase with an O3-type cathode that has been coated with a chloride-based solid electrolyte can create thick, high-areal-loading cathodes that puts this new design beyond previous sodium batteries. Unlike design strategies with a thin cathode, this thick cathode would pack less of the inactive materials and more cathode “meat”, as per the release.

“The thicker the cathode is, the theoretical energy density of the battery – the amount of energy being held within a specific area – improves,” Oh said.

The current research advances sodium as a viable alternative for batteries, a vital step to combat the rarity and environmental damage of lithium. It’s one of many steps ahead.

🔗 Sumber: interestingengineering.com

🤖 Catatan MAROKO133

Artikel ini adalah rangkuman otomatis dari beberapa sumber terpercaya. Kami pilih topik yang sedang tren agar kamu selalu update tanpa ketinggalan.

✅ Update berikutnya dalam 30 menit — tema random menanti!