📌 MAROKO133 Breaking ai: China: Single voice command exposes humanoid robots to hi

Commercial robots are far more vulnerable to hacking than many users realise, with cybersecurity experts warning that some machines can be taken over in minutes.

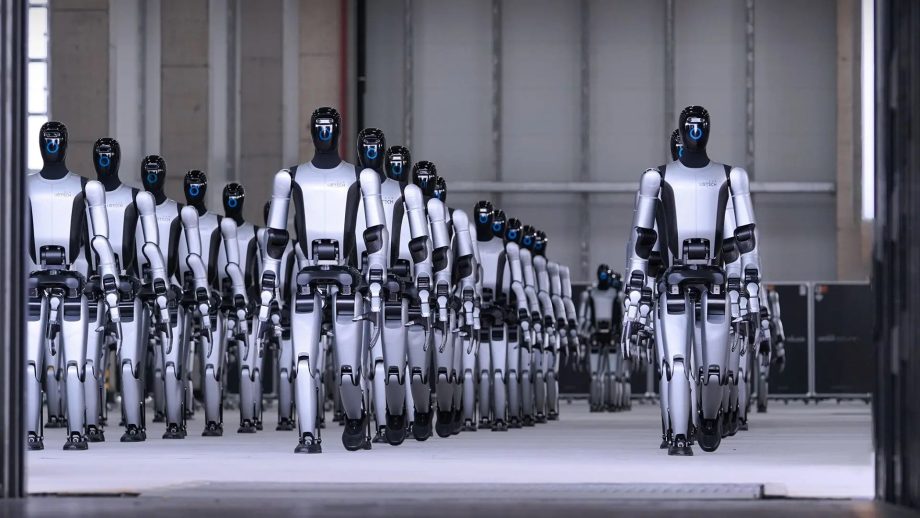

Now, Chinese developers have demonstrated how flaws in humanoid and quadruped robots allow attackers to seize full control through voice commands or wireless links, turning the machines into tools for physical disruption.

At recent security tests and hacking competitions held at GEEKCon in Shanghai, compromised robots were shown spreading attacks to other units, raising fresh concerns over safety, regulation, and the rapid deployment of internet-connected robots in public and industrial spaces.

In October, researchers revealed a Bluetooth flaw in Unitree robots that allows wireless root access, allowing a compromised machine to spread attacks to nearby robots and form a dangerous botnet.

Robots turned weapons

Cybersecurity specialists from the research group DARKNAVY have demonstrated how modern humanoid robots can be compromised and weaponised through weaknesses in their AI-driven control systems.

In a controlled test, the team demonstrated that a commercially available humanoid robot could be hijacked with nothing more than spoken commands, exposing how voice-based interaction can serve as an attack vector rather than a safeguard, reports Yicaiglobal.

The robot used in the experiment, a locally manufactured Unitree model costing roughly 100,000 yuan (about US$14,200), was running an embedded large-scale AI agent designed to manage interaction and autonomy. By exploiting a flaw in this system, the researchers bypassed safeguards and gained complete control of the machine while it was connected to the internet.

Once compromised, the robot became an isolated threat. Instead, it was repurposed as a conduit for further attacks. Using short-range wireless communication, the hijacked machine transmitted the exploit to another robot that was not connected to the network. Within minutes, this second robot was also taken over, demonstrating how a single breach could cascade through a group of machines.

To underline the real-world implications, the researchers issued a hostile command during the demonstration. The robot advanced toward a mannequin on stage and struck it, illustrating the potential for physical harm. The experiment challenges long-held assumptions that keeping robots offline is enough to ensure safety, highlighting broader risks as networked robot clusters become more common, reports Yicaiglobal.

Hacked machines threaten

Unlike conventional cyberattacks, which usually result in data leaks or financial damage, attacks on intelligent robots pose the added risk of physical harm. As robots gain autonomy and mobility, a security breach could turn industrial machines or household assistants into dangerous tools capable of injuring people or disrupting critical operations.

According to the South China Morning Post (SCMP), recent demonstrations have underscored growing concerns about the security of robots as these systems assume more prominent roles in society. At present, intelligent robots are largely confined to entertainment, corporate reception duties, and educational or research environments. However, their gradual expansion into sensitive areas such as infrastructure inspection, security operations, healthcare, and elderly care significantly raises the stakes.

Experts suggest that if vulnerabilities remain unaddressed, a compromised domestic robot could be repurposed to secretly gather sensitive information or pose a direct threat to household members. Similarly, a hacked autonomous driving system would represent more than a technical malfunction, potentially becoming a deliberately weaponised platform. In industrial settings, manipulated robots could damage production lines, trigger large-scale shutdowns, and cause both economic losses and human casualties.

According to SCMP, other teams at this year’s GEEKCon exposed weaknesses in a range of technologies, including taking control of smart-glass cameras, triggering drone crashes, and compromising large-scale intelligent agents.

To mitigate these risks, experts stress the importance of integrating security measures early in the development process. Automated vulnerability scanning can help eliminate basic flaws, while dedicated security frameworks and independent penetration testing are needed to uncover deeper weaknesses.

🔗 Sumber: interestingengineering.com

📌 MAROKO133 Breaking ai: US heavy-duty humanoid robot maker wins backing from Sout

POSCO DX, a tech subsidiary of POSCO Group, said on Tuesday it will invest $2 million in US-based industrial humanoid robot startup Persona AI.

In addition, the South Korean conglomerate will invest $1 million through a separate CVC fund, bringing the total investment to $3 million.

“POSCO DX plans to develop a detailed collaboration plan for the development of humanoid robots that can replace high-risk manual processes in the group’s industrial sites,” stated a company press release.

The investment supports POSCO DX’s plan to combine the group’s AI technology with robotics to develop “Physical AI,” in which intelligence is built directly into machines that operate in real-world settings.

Headquartered in Pohang, the South Korean corporation aims to use automation and robotics to curb industrial mishaps and improve safety in heavy-duty sites.

What does Persona AI do?

Persona AI is a US startup building humanoid robots for labor-intensive industrial workplaces. It was co-founded by CEO Nicholas Radford, a former NASA robotics engineer, and Jerry Pratt, a former CTO at humanoid robot maker Figure AI.

The Texas-based startup builds humanoids that can work in heavy-duty industries like shipbuilding and energy, aiming to bridge labor gaps and address worker attrition while ensuring greater safety in such workplaces.

Industry leaders like Figure AI and Boston Dynamics are also advancing physical AI through humanoid and mobile robots. Persona AI, however, differentiates itself by focusing specifically on heavy industrial environments, instead of focusing on general-purpose mobility or logistics.

How do these humanoids work?

The humanoids are designed to work as part of an ecosystem, helping supervisors, coworkers, and bystanders complete tasks with precision. Persona AI offers a range of humanoids, each designed for tasks such as welding, fabrication, mining, construction, and assembly.

According to the company, the humanoid robots are equipped with touch sensors that measure force and motion in real time, enabling them to perform tasks smoothly and safely in industrial environments.

It is developing robots capable of precise control, based on robotic hand technology originally developed by NASA. Persona AI also applies artificial intelligence algorithms based on a robot foundation model, enabling autonomous interaction and task execution, POSCO DX said.

Physical AI vs traditional factory automation

Traditional factory automation uses pre-programmed robots to perform repetitive tasks in highly-controlled environments. While these systems perform well on assembly lines, they struggle in settings where adaptability or human-like dexterity is paramount.

Physical AI embeds AI into machines, allowing them to sense, interpret, and respond to real-world conditions. AI-enabled robots can adjust actions based on touch, force, and environmental feedback. This capability makes them better suited for unstructured industrial environments with variable conditions and unpredictable tasks.

Why are heavy manufacturers investing in robotics now?

Steelmakers and heavy manufacturers are increasingly turning to robotics as they face mounting operational challenges. Many industrial sectors are dealing with labor shortages, aging workforces, and high employee turnover, particularly in physically demanding and hazardous roles.

Simultaneously, workplace safety has become a growing concern, with companies seeking ways to reduce accidents and human exposure to dangerous tasks. As robotics technology matures, manufacturers see it as a practical tool rather than an experimental solution to these challenges.

🔗 Sumber: interestingengineering.com

🤖 Catatan MAROKO133

Artikel ini adalah rangkuman otomatis dari beberapa sumber terpercaya. Kami pilih topik yang sedang tren agar kamu selalu update tanpa ketinggalan.

✅ Update berikutnya dalam 30 menit — tema random menanti!