📌 MAROKO133 Breaking ai: Cheap core-shell anode pushes sodium-ion battery efficien

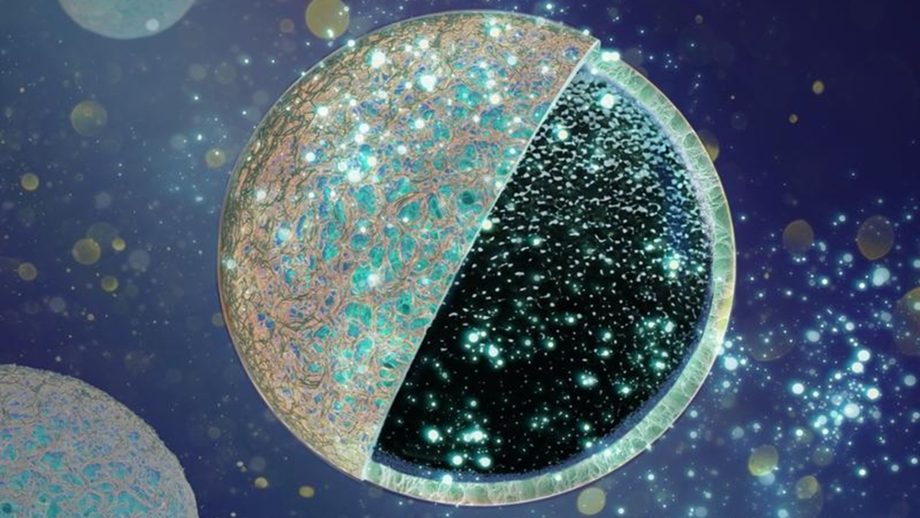

Researchers in Germany have unveiled a low-cost anode that achieved an initial efficiency of 82 percent and could significantly boost the performance of sodium-ion batteries (SIBs).

Developed by scientists at the Federal Institute for Materials Research and Testing (BAM), the new core-shell anode combines efficiency and high storage capacity.

“We realized that large storage capacities and efficient film formation cannot be achieved with sodium-ion batteries using a single material,” Tim-Patrick Fellinger, PhD, BAM expert for energy materials, revealed.

The anode also cuts the massive energy loses during the first charging cycle, one of the biggest drawbacks holding sodium-ion batteries back. The design achieved four times higher initial efficiency than uncoated anodes.

A revolutionary anode

Sodium-ion batteries are widely considered a promising alternative to lithium-ion batteries (LIBs), especially for large-scale energy storage. Sodium is roughly 50 times cheaper than lithium and far less damaging to extract. It is furthermore abundant and environmentally friendlier than lithium.

While lithium-ion batteries routinely reach efficiencies above 90 percent, sodium-ion versions have struggled to get close. This is the result of the irreversible loss of storage capacity during the first charge, as the battery is being manufactured.

Triggered by a chemical reaction between the anode and the electrolyte, which is the conductive liquid in the battery, this loss occurs before the battery is ever put into use.

During this process, electrolyte molecules decompose at the hard carbon anode and penetrate its pores. They reportedly occupy ’empty spaces’ intended for the storage of sodium ions. This process only comes to a halt once a stable protective film has formed on the anode.

Even though the thin protective layer stops further damage, it consumes sodium ions, thus permanently reducing the battery’s usable energy. Lithium-ion batteries avoid he issue thanks to dense graphite anodes. Sodium, on the other hand, cannot be stored in graphite.

To address the challenge, the German researchers created a core-shell anode that separates energy storage from protective film formation. It also has a sponge-like hard carbon core for high storage capacity, and is coated with an ultra-thin outer layer that acts as a molecular filter.

Paving the way for sodium batteries

According to Fellinger, sodium-ion batteries cannot deliver high capacity and efficient film formation with one material. “This is due to the fact that materials better suited for storage are more prone to losses during film formation,” he continued.

The new shell allows sodium ions to pass freely while blocking larger electrolyte molecules that cause unwanted side reactions. As a result, the protective film forms in a controlled way on the shell, rather than deep inside the porous core.

This preserves the anode’s storage capacity and helps the battery maintain its performance over many charging cycles. In lab tests, the anode reached a first-cycle efficiency of 82 percent. This represents a massive increase from just 18 percent for uncoated hard carbon anodes.

“The separation of ‘formation’, the technical term for film formation, and storage allows for the simultaneous improvement of efficiency and storage capacity through separate material developments,” Paul Appel, a researcher working on the project, pointed out.

Appel noted that most battery advances have focused on cathode material, which are nearing their theoretical limits. “With anode materials, on the other hand, it is still completely uncertain where these limits lie and which innovations in material development – keyword: Advanced Materials – can be used to achieve further progress,” he concluded in a press release.

Researchers from BAM, Helmholtz Zentrum Berlin and the Humboldt University of Berlin will further develop the anode material at the Berlin Battery Lab. The study has been published in the journal Angewandte Chemie.

🔗 Sumber: interestingengineering.com

📌 MAROKO133 Hot ai: US lab probes insider sabotage risks in next-generation nuclea

Engineers at the U.S. Department of Energy’s Argonne National Laboratory are testing how insider actions could disrupt passive safety systems in next-generation nuclear reactors before those designs are built and licensed.

Passive safety systems are already used in many operating reactors worldwide and have decades of data supporting their reliability.

Future reactors, including small modular reactors and other advanced designs, rely even more heavily on these systems. That makes understanding their vulnerabilities critical.

“We want to know what would cause these systems to not work. In this project, we’re focusing on bad guys who might have authorized access and knowledge of inside workings. What could they do to make things break?” said Darius Lisowski, group manager of reactor safety testing and analysis at Argonne.

Rather than treating sabotage as a hypothetical risk, Argonne researchers are testing real-world scenarios using large-scale experimental facilities.

Stress-testing passive safety

The work centers on Argonne’s Natural Convection Shutdown Heat Removal Test Facility, which allows engineers to simulate how heat moves through reactor systems when pumps and power are unavailable.

Researchers examined potential insider actions, such as leaving access hatches open or deliberately blocking cooling pathways.

The project began more than two years ago and involved collaboration with Sandia National Laboratories, Oak Ridge National Laboratory, and Idaho National Laboratory.

The team first identified plausible sabotage scenarios and then assessed how likely and damaging those actions could be.

Their findings were compiled into a report titled “Identifying Sabotage Risks and Adversarial Threats to Passive Decay Heat Removal Systems in Advanced Nuclear Reactors,” prepared for the International Atomic Energy Agency.

As expected, the researchers found that nuclear plants are built with multiple layers of protection. Controlled access, alarms, redundancy, and conservative design make successful sabotage difficult.

Even so, the team concluded that some vulnerabilities are worth addressing early, while reactor designs are still flexible.

To test those weak points, Argonne researchers intentionally recreated the most credible scenarios inside the test facility. They blocked cooling paths. They left components unsecured. They measured how systems responded under stress.

“Our research is relevant and applicable to every U.S. nuclear vendor out there,” said Matthew Bucknor, Argonne’s international nuclear security lead.

Designing out weak points

The experiments are not aimed at any specific reactor company or design. Instead, they focus on common features shared across many advanced reactor concepts.

According to the team, identifying risks early can prevent small oversights from becoming serious problems later.

“By using redundancy, focusing on the most severe threats, and meeting strict design tests, we can make sure passive safety features are robust,” Lisowski said.

“Design improvements will happen early, before the next generation of reactors goes into operation.”

The work is funded by the DOE’s National Nuclear Security Administration and has received support for continued research.

As countries look to nuclear energy to meet rising electricity demand from AI, data centers, and electrification, the researchers argue that safety and security must evolve alongside reactor technology.

🔗 Sumber: interestingengineering.com

🤖 Catatan MAROKO133

Artikel ini adalah rangkuman otomatis dari beberapa sumber terpercaya. Kami pilih topik yang sedang tren agar kamu selalu update tanpa ketinggalan.

✅ Update berikutnya dalam 30 menit — tema random menanti!