📌 MAROKO133 Eksklusif ai: Chinese firm’s 620-mile solid-state EV battery retains 7

After leaving Dongfeng’s facilities in central China, the test fleet set out on a long northbound journey to the Mohe Cold Region testing base, located near China’s northernmost border. There, the vehicles will be subjected to intensive winter calibration programs designed to evaluate performance, durability, and system stability in prolonged subzero conditions.

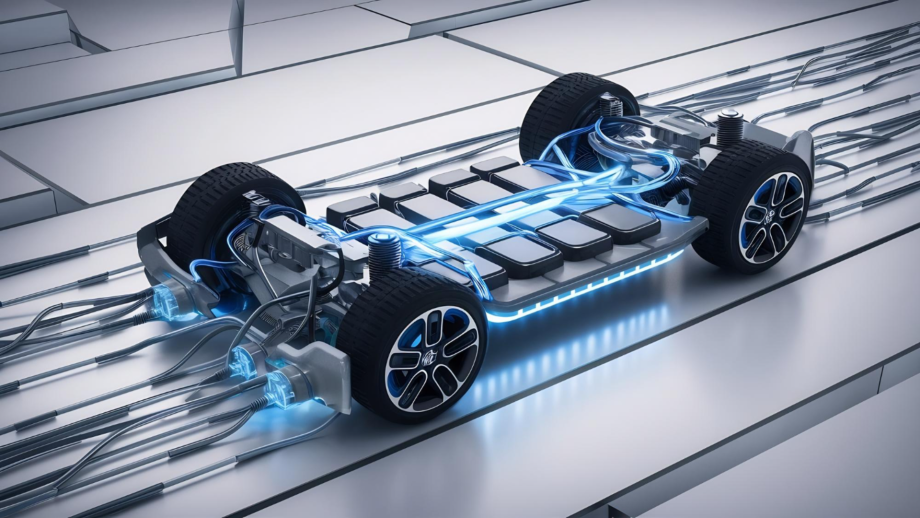

At the core of these trials is Dongfeng’s new 350 Wh/kg solid-state battery, marking a significant milestone in the company’s battery development roadmap. According to official data, the technology is capable of supporting driving ranges of more than 620 miles on a single charge.

The batteries have also demonstrated strong resilience under extreme stress, passing high-temperature box tests at roughly 338°F and retaining around 72 percent of their energy capacity at temperatures as low as -22°F.

Solid-state battery reliability in deep-freeze conditions

The latest phase of testing shifts the focus to how the vehicles perform in sustained deep-freeze conditions, with particular attention on real-world usability. Engineers are evaluating three key areas: driving range at low temperatures, charging performance in cold weather, and long-term durability under repeated thermal stress.

The program includes more than 70 individual tests carried out in environments ranging from approximately -40°F to -22°F. These trials are designed to systematically measure critical performance indicators, including range consistency, charging and discharging efficiency, structural and thermal safety, and how effectively the battery system integrates with the vehicle as a whole under extreme winter conditions.

As part of its broader push into next-generation energy storage, Dongfeng has established a fully in-house development platform that spans the entire cycle from research and development to trial production and pilot testing, CarNewsChina reported.

Through this process, the company has reportedly broken through more than 10 critical core technologies and filed over 180 invention patent applications related to advanced battery systems. Dongfeng’s battery roadmap also outlines a wide spectrum of energy-density targets, with planned products ranging from 240 Wh/kg to as high as 500 Wh/kg.

Moving closer to mass production of solid-state batteries

At the end of last year, Dongfeng highlighted its next wave of solid-state battery technology alongside several new energy vehicle models from its in-house brands. The company disclosed that it has already constructed and brought online a solid-state battery pilot production line with an annual capacity of 0.2 GWh, equivalent to roughly 200 MWh.

According to Dongfeng, this facility will serve as the bridge toward full-scale manufacturing, with mass production of its 350 Wh/kg solid-state batteries for vehicle integration targeted for September 2026. Company representatives also confirmed that the batteries are designed to support a 1C charging rate, positioning them for practical, real-world EV use rather than laboratory-only demonstrations.

Reports in Chinese media indicate that the batteries have undergone thermal stability testing at temperatures of around 338°F, exceeding the national standard threshold of approximately 266°F. While these results come from company disclosures and domestic coverage, they point to a focus on higher thermal tolerance and more predictable behavior under stress as the technology moves through further validation stages.

🔗 Sumber: interestingengineering.com

📌 MAROKO133 Update ai: 3D-printed passive cooling system cools data centers withou

Data centers are under growing pressure as demand for computing power rises and cooling systems struggle to keep up.

Energy use for cooling servers and GPUs is climbing fast, forcing operators to look for alternatives that are both efficient and sustainable.

A European research project has now demonstrated a new cooling approach that could significantly cut energy consumption while extending the lifespan of computer chips.

The solution also opens the door to reusing waste heat for district heating and industrial processes.

The development comes from the recently completed AM2PC project, led by the Danish Technological Institute and Heatflow, along with partners from Belgium and Germany.

The team designed and tested a 3D-printed cooling component aimed at data centers and high-performance computing systems.

In tests, the cooling solution achieved a capacity of 600 watts, exceeding its original target of 400 watts by 50 percent.

The results arrive as countries like Ireland introduce restrictions on data centers due to their growing share of national energy consumption.

Cooling without energy use

Unlike conventional air cooling, the new system uses passive two-phase cooling based on the thermosiphon principle.

A coolant evaporates at the hot surface of the chip, rises naturally, condenses elsewhere while releasing heat, and then returns as liquid through gravity. No pumps or fans are required.

This approach removes heat more efficiently than air or single-phase liquid cooling while consuming no additional energy for heat transport. Keeping chips cooler also helps extend their operational lifespan.

“Besides the actual IT hardware, the corresponding cooling infrastructure is one of the major energy consumers in a data center – and therefore the greatest potential to improve overall system efficiency,” explains Simon Brudler, 3D-printing specialist and senior consultant at Danish Technological Institute.

The need for better cooling is becoming more urgent as GPU power demands increase. A few years ago, GPUs typically consumed 100 to 200 watts. Today, power consumption has climbed to several hundred watts and, in some cases, even kilowatts.

“We are seeing a development where the power density in servers is increasing faster than ever before, and traditional air cooling is simply no longer sufficient. With our two-phase solution, we can remove heat passively without pumps or fans, which significantly reduces the energy consumption for cooling,” says Paw Mortensen, CEO of Heatflow.

Turning waste into heat

The core of the system is a 3D-printed aluminium evaporator developed by Heatflow and the Danish Technological Institute. By using additive manufacturing, the team integrated all necessary functions into a single component.

“By 3D printing the component in aluminium, we can integrate all necessary functions into a single part. This eliminates assembly points, reduces the risk of leaks, and makes the component more reliable,” explains Simon Brudler.

The system removes heat at temperatures between 60 and 80 degrees Celsius. At these levels, excess heat can be fed directly into district heating networks without additional energy input.

It could also support industrial processes in sectors such as food production, textiles, paper, or greenhouse agriculture, provided facilities are located close to the data center.

Traditional air cooling typically removes heat at much lower temperatures, limiting reuse options. While the project did not focus on district heating integration, researchers confirmed the technology enables it.

Beyond operational savings, the project also shows environmental benefits in manufacturing. Using a single recyclable material reduces material use and simplifies end-of-life recycling.

Early life cycle assessments suggest emissions could drop by 25 to 30 percent per unit. The AM2PC project demonstrates how passive cooling and 3D printing could reshape data center energy use.

🔗 Sumber: interestingengineering.com

🤖 Catatan MAROKO133

Artikel ini adalah rangkuman otomatis dari beberapa sumber terpercaya. Kami pilih topik yang sedang tren agar kamu selalu update tanpa ketinggalan.

✅ Update berikutnya dalam 30 menit — tema random menanti!